Mission

Let hope and peace fly to all parts of the world

Guided by the mission “sending hope and peace worldwide,” HEE&HATO provides one-stop solutions for global plastics buyers. With in-house manufacturing and standardized QC, we focus on injection molding machines, extrusion lines, film-blowing systems, and screws/barrels—factory-direct with dependable lead times and optimized total cost. From selection to commissioning, training, and after-sales, we deliver quality and care. Going forward, we will scale our one-stop sourcing platform to make global plastics procurement easier and safer.

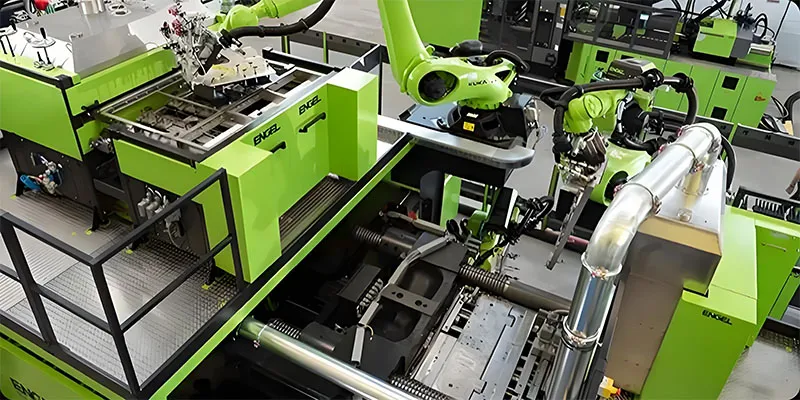

Assembly line

QC Inspection Point

Annual assembly capacity

Serving the country

Factory-direct plastics machinery and turnkey lines—faster delivery, lower energy, day-1 stable output.

Direct shipment from our own factory, transparent prices and controllable delivery time

From model selection, main engine, auxiliary engine to installation, commissioning and training, one-stop service

Standardized quality control and international certification ensure consistency and compliance delivery

Collaborative customization by industry/material/mold to support subsequent expansion and upgrade

Let hope and peace fly to all parts of the world

To be the most trusted and continuously innovative long-term partner in plastics machinery and turnkey solutions worldwide

Customer first, achieving win-win results

A complete product matrix covering injection molding machines, extrusion lines, blown film machines, and screws/barrels, along with supporting peripherals and complete line solutions, factory direct supply, controllable delivery time, and lower energy consumption.

Advanced servo control with fast response, precise PID temperature regulation, and stable long-term operation—designed for efficient, reliable industrial production.

We provide integrated blown film and bag-making solutions for plastic packaging manufacturers, supporting HDPE, LDPE, PP, and biodegradable materials with stable, reliable performance.

Compact and eco-friendly pelletizing solutions for plastic film recycling, enabling on-site edge trim reuse, stable pellet quality, and lower material costs.

Apart from the general screw.special design of special screw is provided in order to satisfy different requirements of plastic resins such as UPVC,PC,PA,CPCA,PPS,PET etc.

In-house machining, welding, coating and final assembly with IQC–IPQC–OQC, online test stations, and rolling in-stock for popular models—faster delivery, stable quality, lower energy.

In-house labs and pilot lines across materials, mechanics, controls and system validation—custom development, rapid prototyping and joint testing to cut ramp-up time and cost.

Click to learn more about our products

SPC/DOE/CFD/CAE throughout the R&D cycle with traceable design-to-validation loops—delivering higher reliability and lower energy consumption.

Click to learn more about our productsInjection molding machines, extrusion lines, blown-film lines, and screw/barrel systems with robotics, thermal control, conveying and in-line QC for turnkey delivery. Injection molding machines, extrusion lines, blown-film lines, and screw/barrel systems with robotics, thermal control, conveying and in-line QC for turnkey delivery.

Use 4 checks: projected area → clamp force, part+runner weight → shot size, material/thickness → screw & speed, cycle/yield → control & process. Send drawing + weight + material + mold info for a recommended configuration.

Packaging, consumer goods, appliances, automotive, connectors, medical, industrial parts—with process suggestions matched to stability, speed, cleanliness, and automation needs.

We run SPC/DOE/CFD/CAE across R&D to build a traceable design → validation → iteration loop for higher reliability and lower energy use.

Through factory testing + traceable records, plus process support after delivery; we can also verify against your target cycle.

By optimizing drive, closed-loop control, thermal efficiency, and standby strategy—savings depend on your part and cycle.

Standard models are faster; custom/lines take longer. Final lead time depends on tonnage, options, automation, and parts availability.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 15653430206,. Or call +86 15653430206 directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.