HDPE High-Speed Blown Film Machine: How to Choose a High Speed Film Blowing Machine Supplier for Stable Bag Production

Running an HDPE line sounds simple—until scrap climbs a […]

Running an HDPE line sounds simple—until scrap climbs and delivery slips. Your plastic film may look fine at first, then gauge swings show up, rolls telescope, and the bag making machine starts rejecting. We fix that by matching the right film blowing machine to your resin, width, output, and downstream needs—then supporting stable mass production.

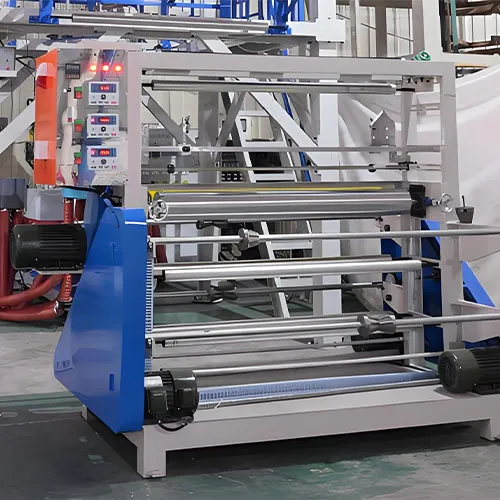

An HDPE High-Speed Blown Film Machine is a high speed film blowing machine designed to extrude consistent plastic film (often for garbage bag, shopping/vest bags, and general packaging) with strong control over thickness, width, and winding. The best choice depends on HDPE/LDPE/LLDPE blend, target width, production capacity, screw and barrel design, air ring cooling, haul-off stability, and reliable after-sales support from the right supplier.

A film blowing machine turns plastic pellets into a continuous tube of plastic film by extrusion. The extruder melts resin, the die head forms a bubble, air expands it, and the bubble gets cooled, flattened, hauled off, and wound. That’s the core of a blown film machine.

“High speed” is not just a marketing word. In real production, high speed means the line can keep stable performance at higher haul-off and winding rates without gauge drift, neck-in instability, or frequent stops. A true high speed film blowing machine uses a stable extruder, consistent cooling (air ring), and strong roller/haul-off control so you get predictable film quality shift after shift.

As a factory-direct, engineering-driven supplier, we see buyers succeed when they define the production goal clearly: target product (e.g., garbage bag), target width, resin recipe (hdpe, ldpe, lldpe, pe blends), and target output. Then we size the line around reality—not wishful numbers.

Most packaging plants don’t run “one resin forever.” They shift between hdpe for strong, stiff film, ldpe for softness and sealing, and lldpe for toughness and puncture resistance. Many customers run blended pe recipes to hit cost and performance targets.

A good hdpe film blowing machine should support:

This matters because resin drives everything: extrusion stability, cooling, bubble behavior, and winding. If you use the wrong die head / air ring / roller settings for your resin, the film blowing machine uses high energy to fight instability, and you lose production efficiency.

If your target width is wrong, your whole factory pays for it—bad edge trim, unstable bubble, weak winding, wasted material. A stable blown film machine project starts with these core choices:

Here’s a simple checklist we use when customers ask for details and price about film lines:

Film Control Checklist (Buyer-Friendly)

Product: garbage bag, vest bags, or general packaging?

Film thickness target (mm film), tolerance, and “must-have” properties

Final width and roll diameter targets

Resin: hdpe only or ldpe/lldpe blend

Downstream: printing machine and bag making machine needs

When these are clear, the film blowing machine setup becomes stable and easy to operate.

Most customers don’t buy only a film blowing machine. They buy a complete system to make finished products. In packaging, the typical flow is:

When these machines don’t match, you lose money. The film line may produce faster than printing. Or printing may become the bottleneck. Or the bag making machine can’t handle your roll hardness and tension, causing jams.

System Matching Tips

If you want stable delivery, treat it as one production line.

Customers often ask: “Can you enhance film transparency?” Yes—but with honest expectations. HDPE film naturally looks hazier than LDPE in many cases. Still, you can improve film appearance and strength through:

Your goal is film quality that converts well, not only visual shine. For garbage bag production, tear resistance, seal strength, and stable thickness usually matter more than mirror-like gloss.

In many markets, the hidden cost is not machine price—it’s uptime. Wear parts decide how often you stop production. That’s why buyers ask about alloy, alloy steel, screw and barrel, and resistance to corrosion.

A reliable film blowing machine uses strong materials where it counts:

This is especially important if you run recycled content, fillers, or high-load recipes. Those can accelerate wear on screw rods and barrel surfaces.

Choosing the right supplier decides your long-term cost. In blown film, small decisions create big outcomes—unstable gauge, constant tuning, repeated downtime. That’s why I recommend buyers evaluate a supplier in three layers:

1) Engineering Fit

2) Delivery Confidence

3) Lifecycle Support

As an engineering-driven, factory-direct supplier, we position ourselves as a one-stop plastic machinery partner—covering equipment, process support, turnkey delivery, and lifecycle service. That’s what global packaging manufacturers and EPC teams need.

What is the biggest mistake when buying a high speed film blowing machine?

Chasing “super high speed” without matching the downstream bag making machine and printing machine. The result is bottlenecks, roll defects, and wasted energy.

Can one film blowing machine run HDPE, LDPE, and LLDPE?

Yes. Many factories run hdpe, ldpe, and lldpe blends on the same film blowing machine, but you must match settings and die/air ring control to each recipe.

How do I choose width for garbage bag production?

Start from your bag size and sealing layout, then work backwards to folding width and roll diameter. Correct width reduces trim waste and improves conversion stability.

Why does the extruder matter so much on a blown film machine?

The extruder controls melt stability and output. If output surges, your film thickness and winding stability suffer, and your plastic film quality drops.

What after-sales service should an overseas buyer require?

At minimum: FAT, commissioning support, training, spare parts list, remote support plan, and a clear warranty period. That protects your delivery schedule.

Is an HDPE blown film machine only for garbage bags?

No. HDPE blown film machine lines can produce many types of packaging film depending on thickness, width, and resin formulation—garbage bags are just one common use.

If you share your target product, resin recipe, width, and output goal, I can recommend a practical HDPE high-speed configuration and a turnkey delivery plan that supports stable mass production and future expansion.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 15653430206,. Or call +86 15653430206 directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.